Functional Applications of Our Cold Galvanizing Compound

ZRC cold galvanizing compound products have a wide range of applications throughout the world, in the most demanding of environments. Our cold galvanizing compound spray and paint are trusted in many industries and global regions to protect important structures and products.

What Assets Can an Anti Rust Paint for Metal Protect?

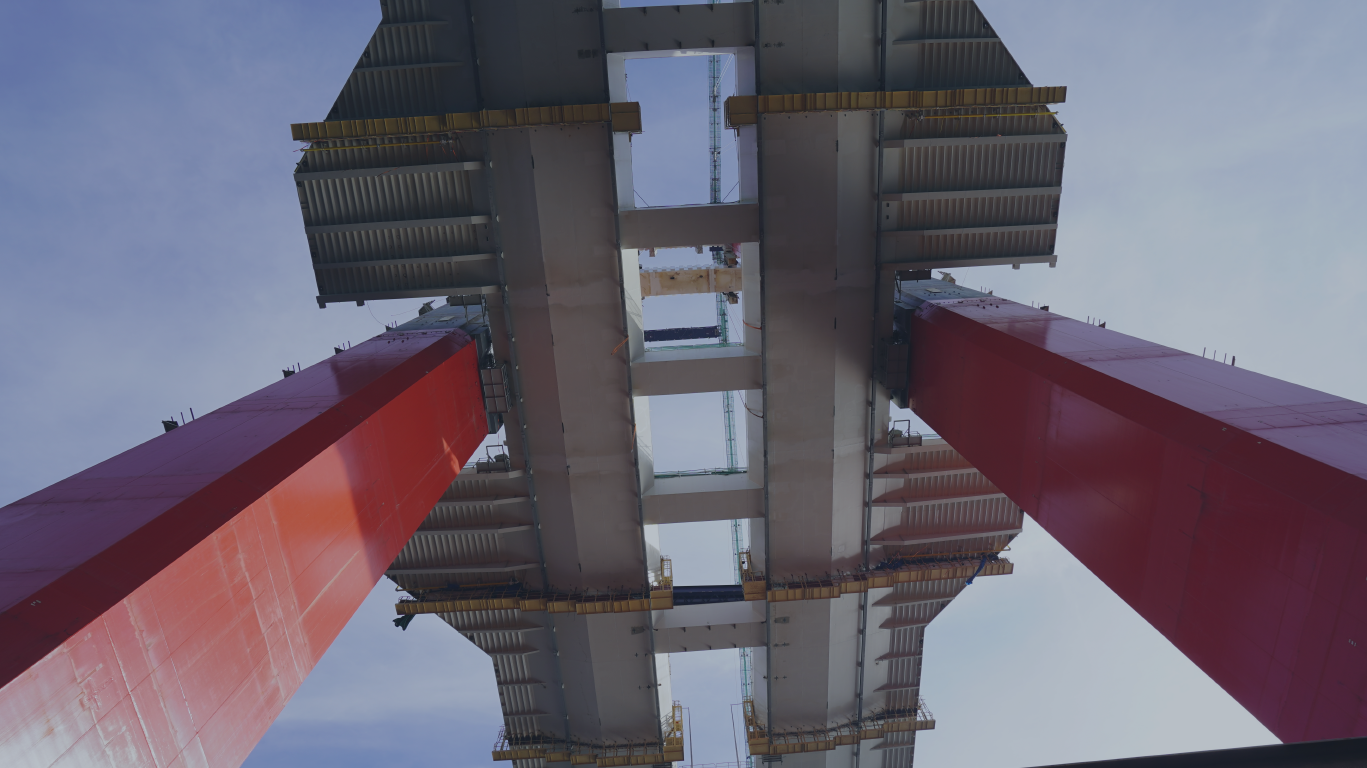

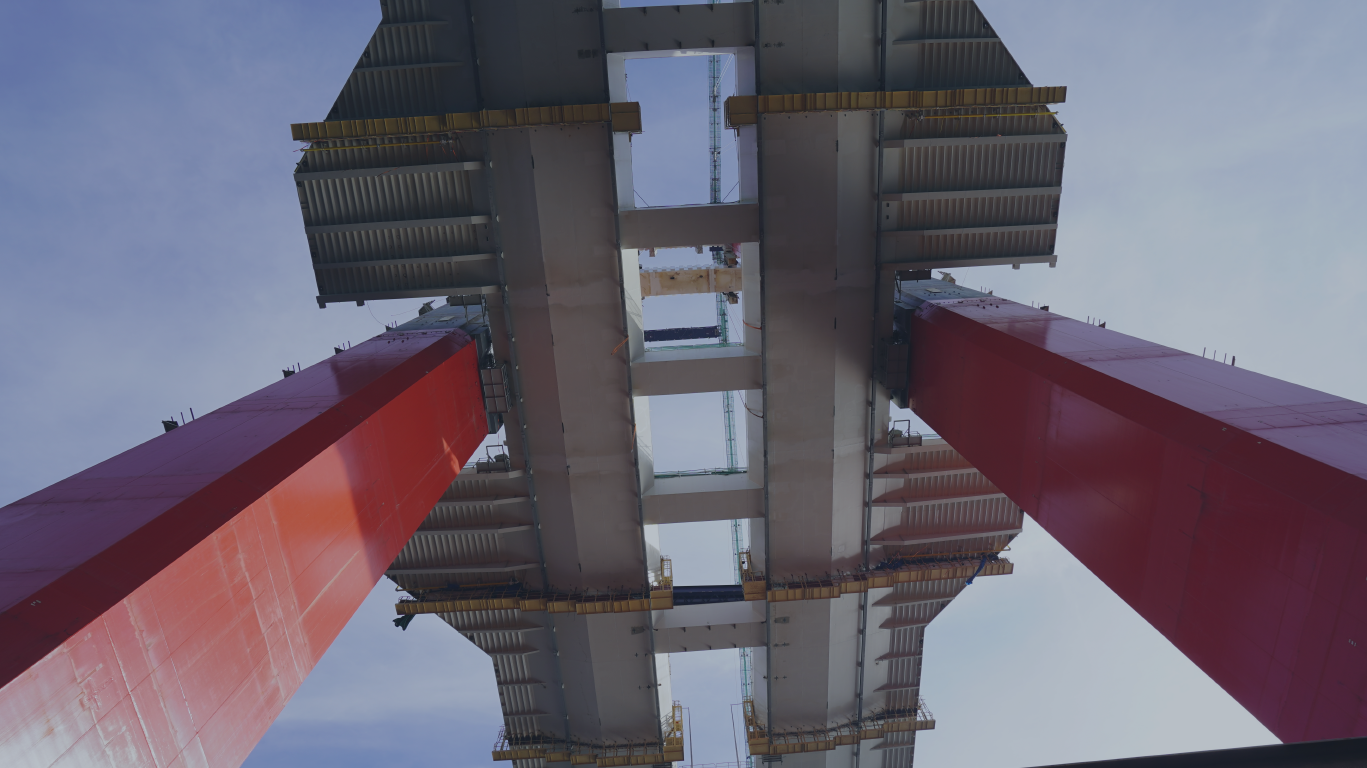

Bridges, Construction, & Public Projects

With unlimited uses, ZRC is used to protect steel structures, including bridges. Our cold galvanizing compound was used on the railings of the Peace Bridge between Buffalo NY and Fort Erie, ON. It is also used on structural channel frames like those of the Bank of America Building in San Francisco CA. It’s leveraged in part of a curtain wall support system in the l.D.S. Center, Minneapolis MN, and in curtain wall mullions in the Republic Bank Tower in Dallas TX. ZRC is specified for infrastructure protection of bridges, guardrails, railings, rebar and other public projects.

Hot-Dip Galvanizing Plants

Major hot-dip galvanizers use ZRC to touch up cut and damaged hot dip galvanized pieces. Our product offers the same protections as hot-dip galvanizing, with greater accessibility and portability.

Cell & Transmission Towers, Other Fabricated Structures

ZRC is used extensively in the fabrication and ongoing maintenance of cell towers, and offers long-term protection for other fabricated structures like solar frames. For transmission towers: ZRC is used as original protection for structural steel and for regalvanizing support cables or worn hot-dip galvanizing.

Industrial Maintenance & Power Plants

ZRC is used for the maintenance of structures and equipment inside and outside industrial structures like petrochemical plants and cooling towers. For power plants, ZRC has many applications in all phases of construction and maintenance. At Seabrook Station, Seabrook, NH, ZRC is used to protect HVAC ductwork throughout the complex.

Marine

Our products can protect above and below the waterline on off-shore rigs, aquaculture pens, and naval applications.

Water & Waste Plants

ZRC is used to protect steel in extremely hostile environments such as water and waste plants.

Bridges, Construction, & Public Projects

With unlimited uses, ZRC is used to protect steel structures, including bridges. Our cold galvanizing compound was used on the railings of the Peace Bridge between Buffalo NY and Fort Erie, ON. It is also used on structural channel frames like those of the Bank of America Building in San Francisco CA. It’s leveraged in part of a curtain wall support system in the l.D.S. Center, Minneapolis MN, and in curtain wall mullions in the Republic Bank Tower in Dallas TX. ZRC is specified for infrastructure protection of bridges, guardrails, railings, rebar and other public projects.

Hot-Dip Galvanizing Plants

Major hot-dip galvanizers use ZRC to touch up cut and damaged hot dip galvanized pieces. Our product offers the same protections as hot-dip galvanizing, with greater accessibility and portability.

Cell & Transmission Towers, Other Fabricated Structures

ZRC is used extensively in the fabrication and ongoing maintenance of cell towers, and offers long-term protection for other fabricated structures like solar frames. For transmission towers: ZRC is used as original protection for structural steel and for regalvanizing support cables or worn hot-dip galvanizing.

Industrial Maintenance & Power Plants

ZRC is used for the maintenance of structures and equipment inside and outside industrial structures like petrochemical plants and cooling towers. For power plants, ZRC has many applications in all phases of construction and maintenance. At Seabrook Station, Seabrook, NH, ZRC is used to protect HVAC ductwork throughout the complex.

Marine

Our products can protect above and below the waterline on off-shore rigs, aquaculture pens, and naval applications.

Water & Waste Plants

ZRC is used to protect steel in extremely hostile environments such as water and waste plants.

Quotes from Our Customers

It’s no secret we’re the industry-leading solution that lasts. Here’s what our customers have to say.

The main advantage of ZRC was that it allowed us to provide galvanized protection on site without delays to the project. Another important factor in specifying ZRC is its true cathodic action. With the volume of heavy traffic passing through the transit shed doors, it is likely they will be scratched. ZRC should provide zinc protection even when the doors are scratched to bare metal.

Sofia Rovira | Principal and executive vice president, DSA; Director, DSA's Building Design Services

I tried several inexpensive galvanizing topcoats, But that proved to be totally inadequate. In fact, they caused more problems beneath the surface of the coating. ZRC was an amazing transformation. My maintenance costs went way down. ZRC indefinitely extended the life cycle of the floats.

Phil Donahue | Waveland Marina, Hull MA

The steel railings have held up very well, especially considering their constant exposure to the corrosive effects of moisture from Lake Erie and the Niagara River, the severe Buffalo winters, and the light road salting in the area.

George Nicholas | President, Essen Contracting Company, Buffalo NY

Become a Dealer of ZRC Cold Galvanizing Compound Spray and Paint

ZRC Worldwide created zinc coating technology to combat corrosion and has been a worldwide leader in the space for 70 years. In any given year, ZRC is specified more than all the other products combined. When you become a ZRC dealer, people will come directly to you because they know our products offer the rust prevention solutions they need. When you carry our products in your store, you’re going to have customers walking in the door asking for them. We guarantee it!

-1.png?width=400&name=ZRC%20Website%20image%20Can%20(1)-1.png)